Differences between inkjet and thermal printers

Picture Quality

Inkjet printers are one of the most prolific methods of digital printing and can produce high quality images at a low initial cost. The two main determinants of print quality are resolution, the substrate used for printing, and the number of levels that can be printed per dot. Any moisture or dampness can damage the prints. Thermal printers produce high quality prints with glossy, protective finishes and better color saturation. Because thermal printers have fewer moving parts, they are durable.

Printing Process

Inkjet printers use liquid ink rather than ribbons and heat to produce an image - the printer jets thousands of tiny droplets of ink onto a substrate (such as paper) pixel by pixel to create an image. Thermal printers use heating elements to burn or melt dot-matrix pattern characters on special paper. This is a cost-effective industrial printing technique that applies dried wax-based pigments to a substrate, such as paper, that uses heat. The print head does not move across the page; instead, it scans the paper and prints a line of characters.

Equipment Costs

Although thermal printers do not require ink, the special materials used in the printing process can be quite expensive. However, in bar code applications, no other printing technology can beat the image clarity of thermal printing at anywhere near the price. Thermal inks are usually a little more expensive than inkjet cartridges. Inkjet printers are relatively inexpensive, and ink cartridges are cheaper than thermal inks. In addition, cartridges can be refilled and reused, thus saving money.

Applications

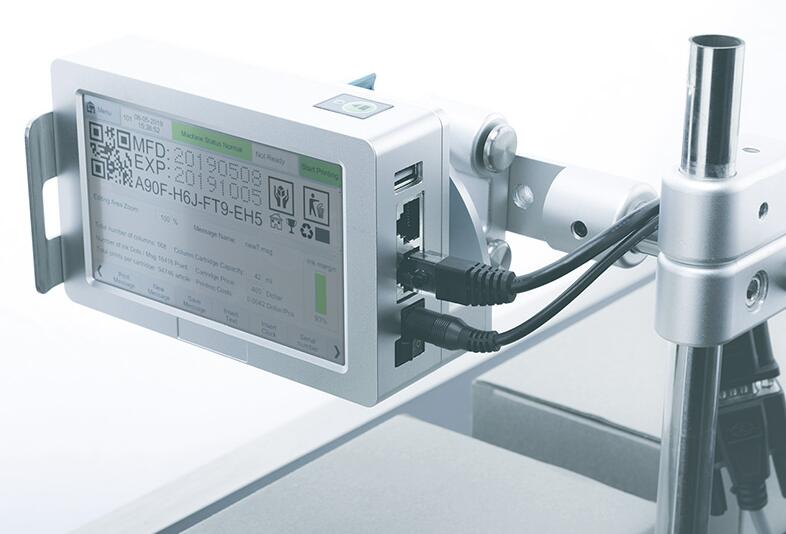

Thermal printers are widely used for bar code printing, credit card receipts, airline tickets, and school records. Commercial applications for thermal printers include kiosks, gas stations, POS systems, shipping labels, etc. Inkjet printers are widely used in office and industrial applications for wide format printing. They are primarily used for a variety of industrial applications such as signage, 3D printing, high-speed coding, mail addressing, package marking, billboards and banners.

Although thermal and inkjet printing are both widely used printing methods, they are distinctly different processes. Thermal printers use a heating element to burn or melt dot-matrix patterned characters into special thermal paper. Thermal printing is widely used for battery-powered handheld printing devices, bar code printing and credit card receipt printing. Thermal printers are more sustainable and reliable than inkjet printers because they have fewer moving parts. Inkjet printers produce characters by ejecting a precisely controlled stream of ink dots onto the paper. Inkjet printers are relatively inexpensive to purchase and maintain.

Inkjet printer

回复删除