The equipment with continuous inkjet technology function is called continuous inkjet printer. Its working principle: the ink with a certain pressure is split into the same frequency, the same size, and the ink droplets with a certain distance are ejected from the nozzle under the oscillation of the crystal oscillator. Then, the ink droplets are charged separately when they pass through the charging tank, and the amount of electricity charged is controlled by the central processing unit CPU; the charged ink droplets continue to travel until the deflection electric field is deflected under the action of the electric field force and ejected from the notch in front of the nozzle. Spray on the surface of the product to form various characters, patterns and other signs. The uncharged ink drops enter the recovery pipe and re-enter the ink circulation system inside the machine.

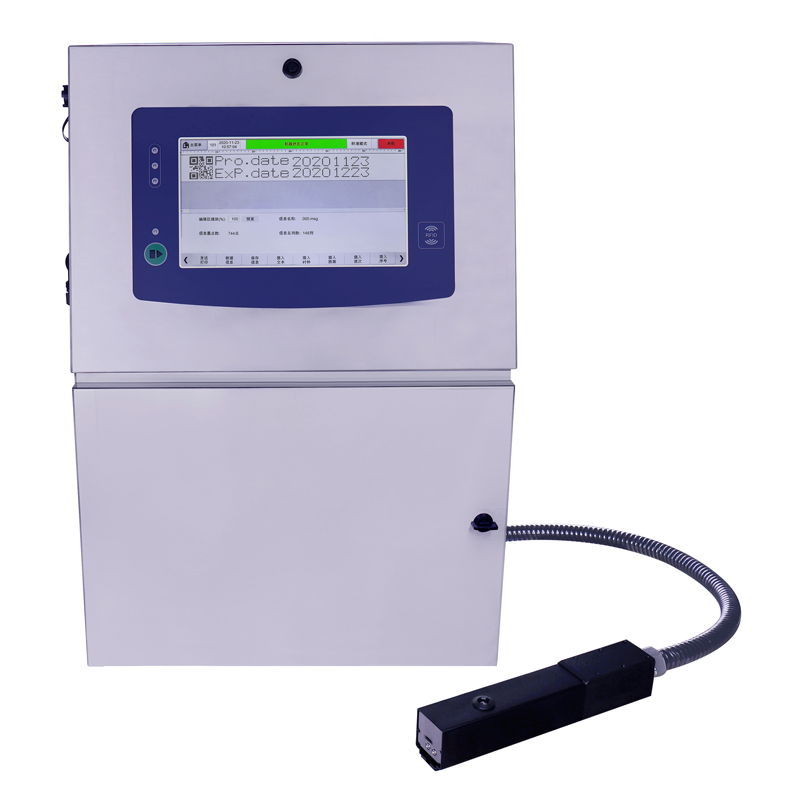

Continuous Inkjet Printer

Features of continuous inkjet printer:

The nozzle and the object are non-contact, it can print up to 5 lines. Fast printing speed, single-line printing can reach 576m/min.

The ink is fast-drying, generally it dries in less than one second when sprayed on the object;

The ink has strong adsorption and is not easy to wipe off.

Because of the above-mentioned characteristics, continuous inkjet printers have been widely used in online product coding on industrial assembly lines. The coding content includes: production date, batch number, serial number, trademark, product name, specification model, bar code, anti-counterfeiting mark, etc.

Our company also has Continuous Inkjet Printer on sale, welcome to contact us.

评论

发表评论