With the complexity of customer requirements, the diversification of market application requirements, the overall supporting automation and the simplification of personnel, TIJ inkjet printers have gradually entered everyone's field of vision. High efficiency and fast speed have become two important keywords at the core. Today, Inkjet Label Printer Supplier will share with you the industry technical support in this regard, what is the TIJ inkjet printer, and analyze its market applications and development trends.

TIJ Inkjet Printer

What is TIJ printer? What is its working principle in simple terms?

Simply put, TIJ inkjet printer is what we often call thermal foam inkjet printer.

The thermal foaming inkjet printer is simple to operate, easy to install, and powerful in printing. It can print real-time data, barcodes, two-dimensional codes, databases, etc., and has powerful editing functions. It can edit the text height up to 76.2mm. Code machine.

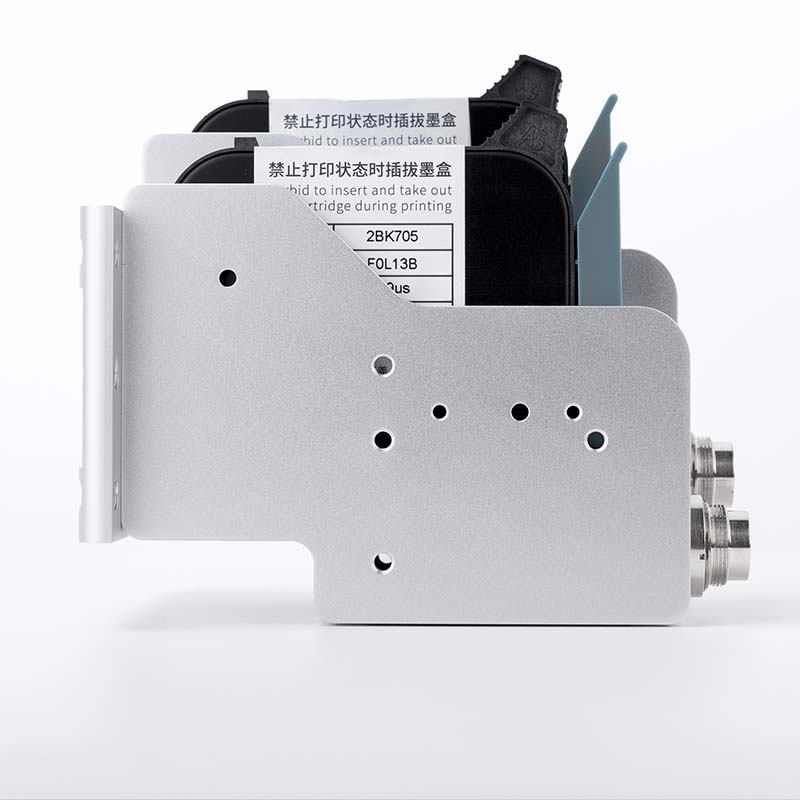

The structure is simple, generally composed of three parts: the host, power supply, and print heads. It does not require filters, cleaning and maintenance. It can achieve multi-head printing, and supports up to 6 print heads to work at the same time. You can replace other color inks at any time, such as black, yellow, Red, blue, white and other colors.

Introduction to the working principle of thermal foaming: Using thin-film resistors, the ink is instantly heated in the ink ejection area (instantly heated to above 300 ℃) to forma big bubble and expand at a very fast speed, forcing the ink Drops are ejected from the nozzle to form the required text, numbers, and barcodes.

When the bubble continues to expand, it disappears back to the resistor; when the bubble disappears, the ink in the nozzle shrinks back. Then the surface tension will generate suction, and then draw new ink to replenish the ink ejection area to prepare for the next cycle of printing.

Our company has TIJ Inkjet Printer on sale, welcome to contact us.

评论

发表评论