As a TIJ System Supplier, share with you.

Through the ink drop ejection process outlined above, TIJ printers have the following advantages:

Low maintenance/high reliability

The ink cartridge system used by TIJ printers does not require print head service. If there is a problem, simply replace the ink cartridge with another one, and the problem can usually be easily resolved within a few seconds.

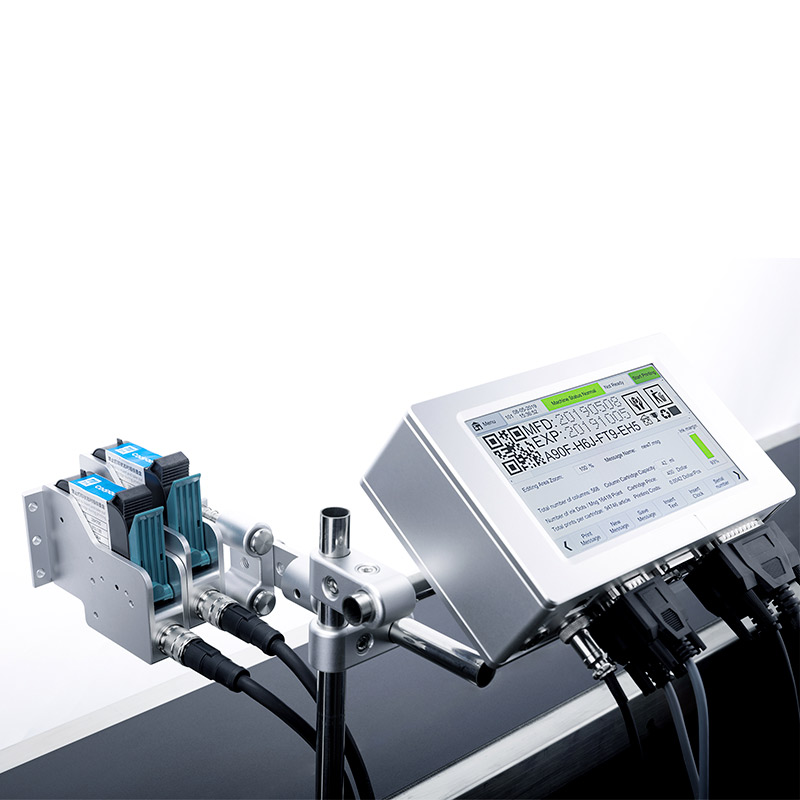

TIJ Inkjet Printer

The four-step thermal inkjet printing process is much simpler than continuous inkjet printers, which use ink-filled ink cartridges, boosters and piezoelectric print heads for operation. Therefore, TIJ machines can create high-quality print quality for many years without maintenance, while CIJ printers require regular expert services to get the best performance.

In addition to the convenience of using TIJ printers for the aforementioned maintenance, the total cost of ownership is also lower.

fluidity

In addition to reducing maintenance costs, the simplicity of the ink droplet ejection process also makes TIJ machines more compact than other printer types. For example, after installation and full of ink, many CIJ machines may weigh close to 100 pounds. This requires fixing them in a fixed position along the production line.

For operations that require more printer mobility, TIJ will be a better choice, because even when fully equipped, these devices only weigh 1-2 pounds. In order to take advantage of this lightweight structure, TIJ printers are available in both easy-to-adjust installation type and hand-held type.

Versatility of substrate specialization

Although in the past TIJ models were usually limited to printing only on certain substrates (usually paper and cardboard), with the development of printing technology, the list of codeable surfaces has greatly increased. Now, depending on the model in question, the TIJ printer can be used to print on the following printers:

Porous substrates: including paper, cardboard, sponge, untreated wood, etc.

Semi-porous substrates: including waxed surfaces, plaster, concrete, coated paper, etc.

Non-porous substrate: including plastic, metal, wood varnish, glass, etc.

Our company also has TIJ Inkjet Printer on sale, welcome to contact us.

Getting a professional printer with cheap ink cartridges is not easy but trusted service providers have the both options.

回复删除